3310 Buckingham Road, Glendale California

Completed in 2009, the Buckingham Villa is the culmination of years of research, inspiration and hard work. Many people were involved in the process that took over 10 years from start to finish. This is just some of the story of this true labor of love...

DESIGN

The Villa was designed and built by Escott O. Norton. He comes from a long line of quality home developers, going back to his great grandfather J. C. Norton who developed one of the first communities in Phoenix AZ, now the Del Norte historic district.

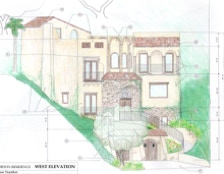

The inspiration for the Villa came from many European visits, specifically to the northern regions Italy and Spain. The hillside villages with centuries old structures that had been adapted with each generation were the starting point for this challenging hillside lot. Other inspirations were castles and a 16th century monastery in Spain.

Building Plans were then produced with multiple goals, the home would visually be true to the ancient buildings that inspired it, would be engineered and built as strongly as possible, AND contain the latest in modern “green” construction techniques. The plans were submitted to plan-check which required more than 2 years to process because of the complex design and engineering, and the use of new building technology. Finally, on May 21, 2007, the building permit was issued. Now the REAL work began!

The lot was purchased in 1999, and over the next 4 years, three different homes were designed. Every time a design was finalized the City of Glendale amended the Hillside Zoning ordinance, requiring a new design. Finally, in 2004, Mr. Norton presented his proposal to the Design Review Board, where it was enthusiastically given a 1st time Final Approval.

TECHNOLOGY

ICF (Integrated Concrete Form) Construction

All structural elements of the Villa are built with poured-in-place concrete and steel, using a forming system generically called ICFs. The ICF block is two 2.5” walls of expanded poly-styrene (styrofoam) held apart by web spacers. These blocks lock together much like LEGOS and are stacked to form walls. Steel reinforcing bar (rebar) is inserted at regular intervals. Concrete is then pumped in to the cavity to form the structural wall. The ICF form stays in place as insulation and the finish is attached with screws to the web spacers. This creates a super insulated and very strong structure.

Floors and Ceilings are also formed using a similar technology, called Am-Deck. Temporary shoring is built, steel joists are set on the shoring, and the foam forms snap on to the steel joists. When the concrete is poured it forms the new slab with integrated concrete I-beams. Once the concrete reaches full strength, the shoring is removed and used at the next pour.

Keyless Entry

The main entry door is outfitted with a keyless lock option. Once the owners fingerprints have been scanned by the lock, a simples swipe of the finger and the lock opens. Locking it when leaving is even easier, a few simple taps on the sensor and the door is locked!

Central Vacuum

The Villa is equipped by a central vacuum system with 2 retractable hoses, one on each floor. Simply pull the hose out to the desired length, attach the handle and turn on via the remote button on the handle. When finished the hose retracts back into the wall with suction. The motor unit is in the garage, for easy emptying.

Thermador Cooking Appliances

The gourmet kitchen is equipped with top of the line Thermador cooking appliances.

The gourmet kitchen and the roof deck kitchen are both equipped with Sharp Microwave drawers.

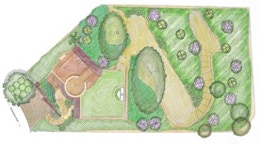

The roof lawn is automatically irrigated with a special drip system installed under the grass. There is no overspray and no evaporation, so the lawn can be used while it is being watered.

BUILDING

Construction of the Villa was supervised by Escott O. Norton. Subcontractors were brought in for some areas, but most of the crews worked directly with Escott, his father Oakley, and other family members. In many cases, because of the unique specifications, materials and building techniques, Escott needed to educate the crews working on this project. (click the photos to enlarge)

FINISHED PHOTOS

Each room is inspired by some of the Norton’s favorite places in Europe: (click the photos to enlarge)

Copyright 2022 EON Design Co. www.EONDesignco.com